We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Read our Privacy and Cookie Policy.

A tyre changing machine removes and installs tyres on the rim, while a wheel balancer ensures that the assembly spins evenly without vibration. Both services are essential for safety and tyre longevity.

Why wheel balancing matters

After new tyres are installed, the wheel assembly must be balanced. Tyre manufacturers balance tyres during production, but final balancing is done once the tyre is mounted on the rim. Without balancing, tiny weight differences cause vibrations and uneven wear. Balanced wheels roll smoothly and keep the tread in contact with the road.

Tyre wear affects balance

Even after a wheel is balanced, normal tread wear and pressure changes can throw off the balance over time. Regular balancing—typically every 6,000 miles—extends tyre life and reduces vibration. Unbalanced wheels can skip or bounce, causing uneven tread wear and potentially leading to blowouts.

Signs of imbalance

Vibration at certain speeds, uneven tread wear or a steering wheel that shakes are common signs that wheels need balancing. If the tyres are balanced but vibrations persist, the issue may lie in the suspension or steering system.

How tyre changing and wheel balancing work together

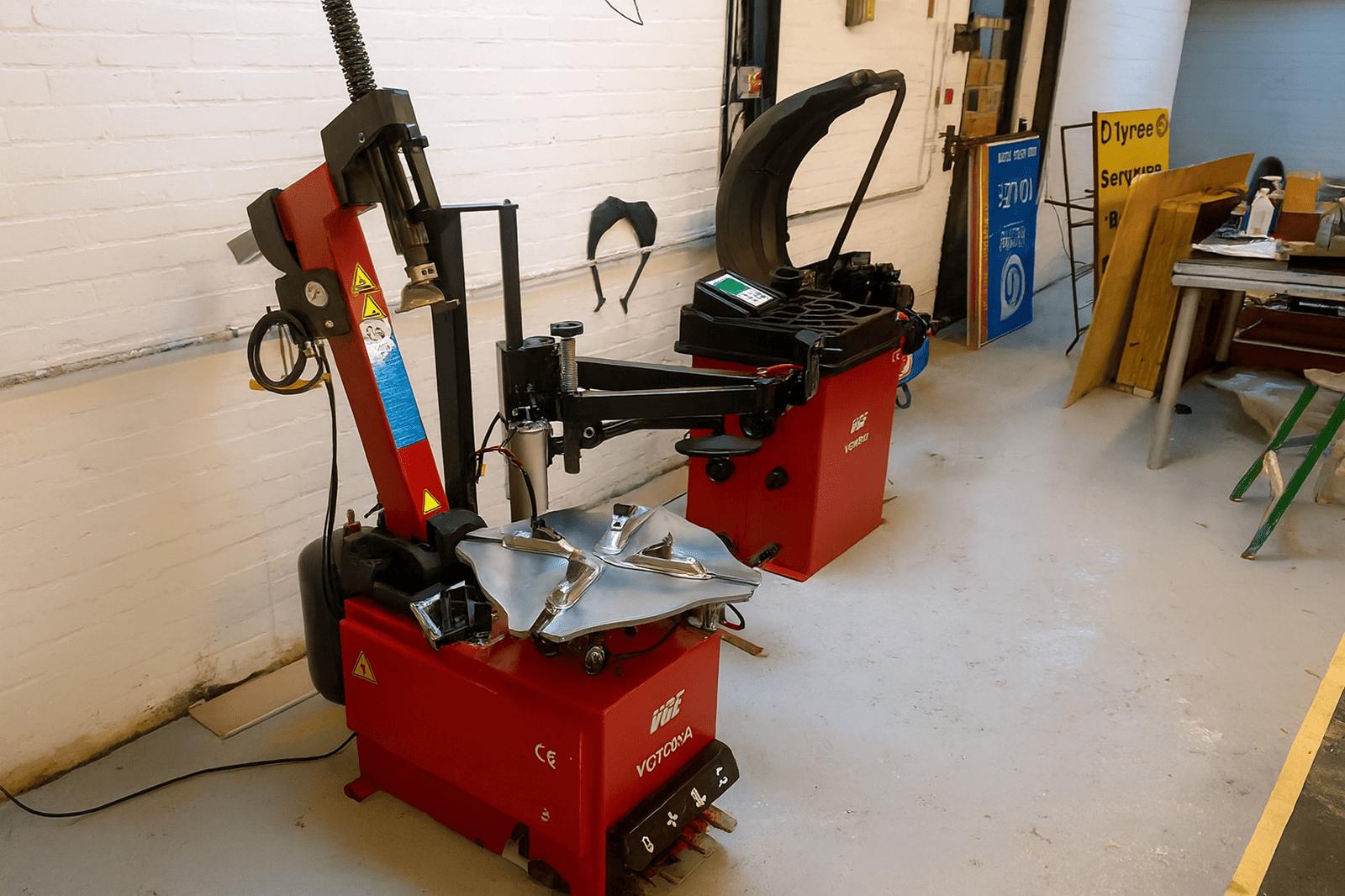

- Tyre changing removes the old tyre and mounts a new one. Modern tyre changers protect rims and speed up the process.

- Wheel balancing uses a machine that spins the tyre and rim assembly to locate weight imbalances. Small weights are then added to the rim to correct the imbalance.

Offering both services ensures that customers leave with new tyres that are safe, smooth and long‑lasting. After performing a tyre change, always balance the wheels before delivering the vehicle to the customer.

To explore our full range of tyre changers, visit the product page. For comprehensive safety and maintenance advice, read our safety guide and maintenance guide.