We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Read our Privacy and Cookie Policy.

Selecting the right tyre changer is one of the most important decisions a garage or tyre shop will make. The right machine increases throughput, protects customer wheels and keeps your technicians safe. An ill‑suited model wastes space and money. Use the following considerations to ensure you invest wisely.

Assess your shop’s needs

- Shop size and layout – Compact workshops should opt for smaller units; large garages may justify larger machines fitted with helper arms and wheel lifts.

- Workload – High‑volume shops need heavy‑duty models built for constant use, while smaller shops can manage with simpler machines.

- Vehicle types serviced – Machines designed for passenger vehicles may not handle motorcycle wheels or large commercial tyres. Choose a unit that matches the range of wheels you work on.

Manual vs electric vs automatic

- Manual machines are inexpensive and portable but require considerable physical effort. They suit shops on tight budgets with low throughput.

- Electric machines rely on motors and eliminate the need for an air compressor, but you must ensure your premises has the correct electrical supply.

- Automatic machines offer minimal manual intervention and are ideal for mounting run‑flat or low‑profile tyres. They automate most of the work and improve technician efficiency.

Rim‑clamp, centre‑post and other designs

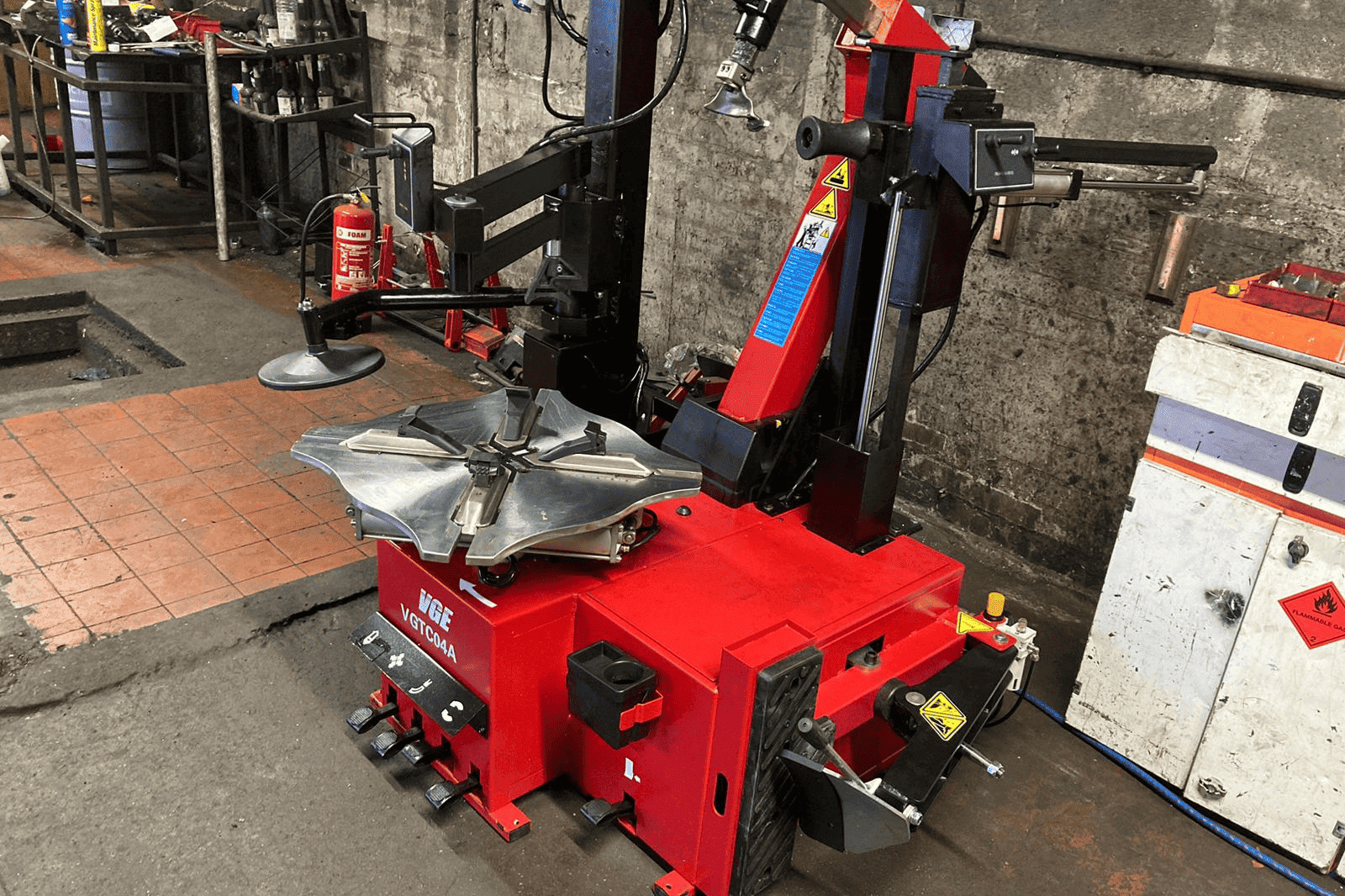

- Rim‑clamp changers use a tabletop with adjustable clamps that grip the wheel from the rim. They handle a variety of sizes and are popular for versatility.

- Centre‑post changers secure the wheel via a post through the hub. This method protects delicate or specialty wheels and reduces the risk of rim damage.

- Swing‑arm vs tilt‑back – Swing‑arm units have a mount/demount arm that moves away from the turntable, offering a wide clamping range. Tilt‑back models tilt the entire column to create more space and often include helper arms for difficult tyres.

- Leverless and heavy‑duty machines – Leverless technology uses bead lifters and clamps to remove tyres without pry bars, reducing damage. Heavy‑duty changers handle large off‑road or agricultural tyres and use hydraulic clamps.

Key drivers to consider

- Vehicle volume – How many vehicles you service daily or weekly influences the capacity you need.

- Shop dimensions – Machines take up floor space. A unit that is too large hampers workflow; too small a unit may not handle your workload.

- Technical features – Look for helper arms, integrated wheel lifts, extended clamps and automation that protect rims and reduce operator fatigue.

- Budget and ROI – Balance cost against expected return. Don’t assume the most expensive model is best; use a return on investment calculator to estimate payback time.

Budgeting and return on investment

Evaluate the machine’s cost relative to labour savings, technician morale and customer satisfaction. Premium changers can reduce labour time per job and minimise rim damage, directly influencing revenue. To estimate payback time, input daily job volume, revenue per job, labour rate, minutes saved per job and the cost of the new machine into an ROI calculator. Many shops find that a high‑performance machine pays for itself within six to twelve months.

What to do next

Once you’ve identified the right type of machine for your shop, consider reading our guides on tyre changer maintenance and safety to ensure your investment performs well and keeps your team protected.